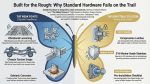

Why Standard Hardware Fails on the Trail: A Guide to Heavy-Duty Latches and Hinges for Trucks

There is an old saying in the overlanding community: “The trail finds the weak points you didn’t know you had.” You can spend thousands on suspension upgrades, 35-inch tires, and engine tuning, but a build is often only as reliable as its smallest components.

When you are miles from the nearest paved road, a failed latch on a swinging tire carrier or a rusted-out hinge on a utility canopy isn’t just an annoyance—it’s a liability. For DIY enthusiasts and custom truck builders, understanding the difference between residential hardware and industrial-grade components is the key to building a rig that survives the journey.

Building for the Rough: Why Industrial-Grade Hardware is Essential for Custom Vehicle Builds

Most hardware found in big-box home improvement stores is designed for static environments. A gate hinge on a backyard fence sits still 99% of the time. Conversely, a hinge on an overland rig is subjected to a chaotic mix of dynamic forces, thermal expansion, and chemical attacks. To build a “bulletproof” truck, we must first understand the enemies of hardware longevity.

The Hidden Stressors: Vibration and Torsion

The most destructive force on a vehicle isn’t a large impact; it is the constant, high-frequency vibration caused by washboard roads (corrugations).

Vibrational Loosening: Intense vibration can overcome the friction that holds standard nuts and bolts together. It causes internal parts of cheap latch mechanisms to disintegrate or jam.

Chassis Flex (Torsion): When a truck articulates over a rock or uneven terrain, the chassis twists. If you have mounted a rigid box to the bed, that torsion transfers to the hardware. Standard hinges often bind or snap under this stress because they lack the tolerance required for heavy-duty applications.

Securing Your Cargo Systems

One of the most popular DIY projects for truck owners is the custom drawer system or the utility canopy fit-out. The goal is organization, but the result is often a cacophony of noise.

When you are fabricating a custom drawer system or upgrading a canopy for overland travel, the latching mechanism is often an afterthought. However, a loose latch means constant rattling and potential gear failure on washboard roads. This is why experienced builders often look beyond standard auto parts stores. Instead, they source industrial-grade components from specialized manufacturers like Kunlong, whose compression latches are designed to withstand the vibration of heavy machinery. These mechanisms actively pull the door tight against the seal, compressing it to eliminate movement and vibration noise entirely.

Material Science: Fighting Elements on the Road

If vibration doesn’t kill your hardware, the environment will. Mud, road salt, and coastal sea spray create a highly corrosive environment.

304 vs. 316 Stainless Steel: While 304 stainless is common, it can still develop surface rust in salty environments. For exterior mounting on expedition trucks, 316 (marine grade) is the superior choice due to its molybdenum content.

Zinc Alloy & Plated Steel: Acceptable for interior cabin use, but these will degrade rapidly if exposed to the elements on a roof rack or bumper.

It isn’t just about tensile strength; it comes down to basic chemistry. One of the most common rookie mistakes is bolting stainless steel hardware directly onto an aluminum canopy or flatbed without an insulating barrier. This creates a battery effect known as galvanic corrosion. In the presence of an electrolyte—like salt spray or even rainwater—the aluminum will sacrifice itself, corroding rapidly around the mounting points and weakening the structural integrity of your build.

Key Takeaways

Area

Key Takeaway

Impact/Data

Mechanisms

Replace standard latches with compression types.

Zero vibration noise/rattle

Materials

Mandate 316 Marine Grade Stainless Steel.

Prevents salt/chemical rust

Assembly

Isolate dissimilar metals (Steel vs. Aluminum).

Stops galvanic corrosion/failure

Installation

Require backing plates and thread lockers.

Resists dynamic chassis torsion

Installation Best Practices for Long-Term Durability

Even the best industrial hardware will fail if installed incorrectly. Follow this checklist to ensure your modification lasts as long as your truck:

Use Backing Plates: Never bolt a heavy hinge through a single sheet of sheet metal. Use a backing plate on the inside to distribute the load over a wider surface area.

Chemical Locking: Use a medium-strength thread locker (like Blue Loctite) on all metal-to-metal fasteners subject to vibration.

Nyloc Nuts: For adjustable components, use nylon-insert lock nuts which resist backing off better than standard split washers.

Isolation Washers: Always place a nylon or rubber washer between dissimilar metals (e.g., steel bolts on aluminum panels) to stop electrolysis.

Building a rig for the rough isn’t about buying the most expensive gear; it’s about selecting components that are engineered to survive the environment you plan to explore.